Conventional Vertical Milling Machines

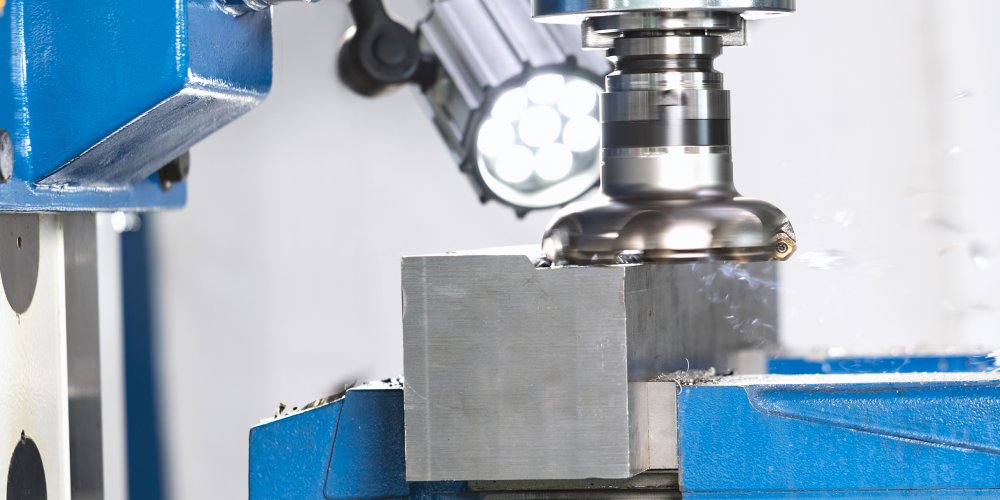

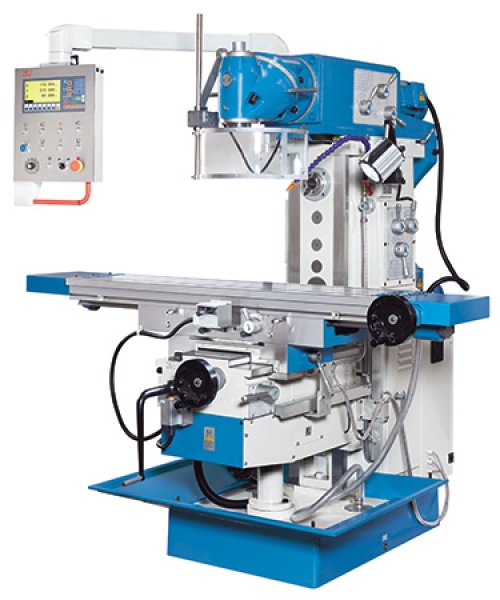

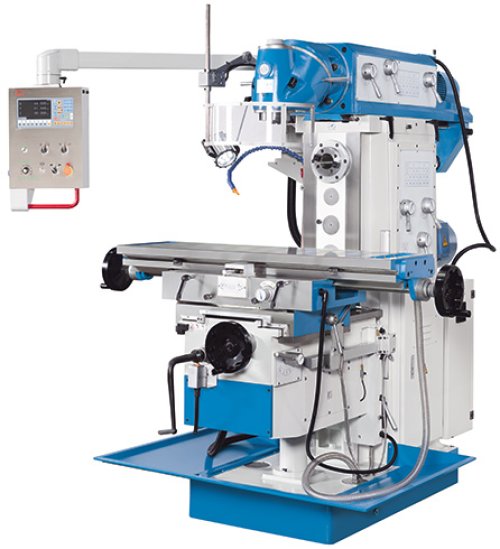

The most popular style of milling machine in the world, the vertical mill, or knee mill, is a versatile machine for industrial applications. Featuring a vertical spindle with a quill, these machines are ideal for single sided milling and drilling. Common table sizes are 230x1250 and 250x1400 and come with a 40 taper spindle. KNUTH includes many standard features on our vertical milling machines including: air powered draw bar, X or X & Y powered axes, DRO and coolant system.

The most popular style of milling machine in the world, the vertical mill, or knee mill, is a versatile machine for industrial applications. Featuring a vertical spindle with a quill, these machines a...

read more